Air-Cooled (Chiller)

A type of chiller that exhausts the heat absorbed from the process to the surrounding air. Most of the chillers listed on this website are air-cooled (unless otherwise specified). The cooling efficiency of air-cooled chillers is directly related to ambient air temperature.

Ambient Air Temperature

The temperature of the room in which the Circulator, Chiller, etc., is located. Refrigerated equipment is generally required when the application temperature must be controlled near or below the ambient room temperature.

Ambient Temperature Range

This represents the highest and lowest ambient air temperatures at which the Circulator or Chiller was designed to operate.

Calibration Capability

The ability to match the reading of a device to that of a known standard or another device. PolyScience Circulators, Chillers and Digital General Purpose Water Baths all feature calibration capability.

Centrifugal Pump (magnetic drive)

Available on many PolyScience Recirculating Chillers, this type of pump provides higher relative flow rates at lower pressures and is suitable for applications that are in close proximity to the chiller or require lower pressure. Centrifugal pumps are generally more sensitive to pressure drops than other types of pumps.

Chiller/Recirculating Chiller

A closed-loop refrigerated system designed to cool an external device. In general, Chillers have more cooling capacity and are capable of higher flow rates and higher fluid pressures than can be achieved by Refrigerated Circulators.

Circulator/Circulating Bath

A general term referring to a category of temperature control devices. See Refrigerated/Heated Circulating Bath, Heated Circulating Bath and Immersion Circulator.

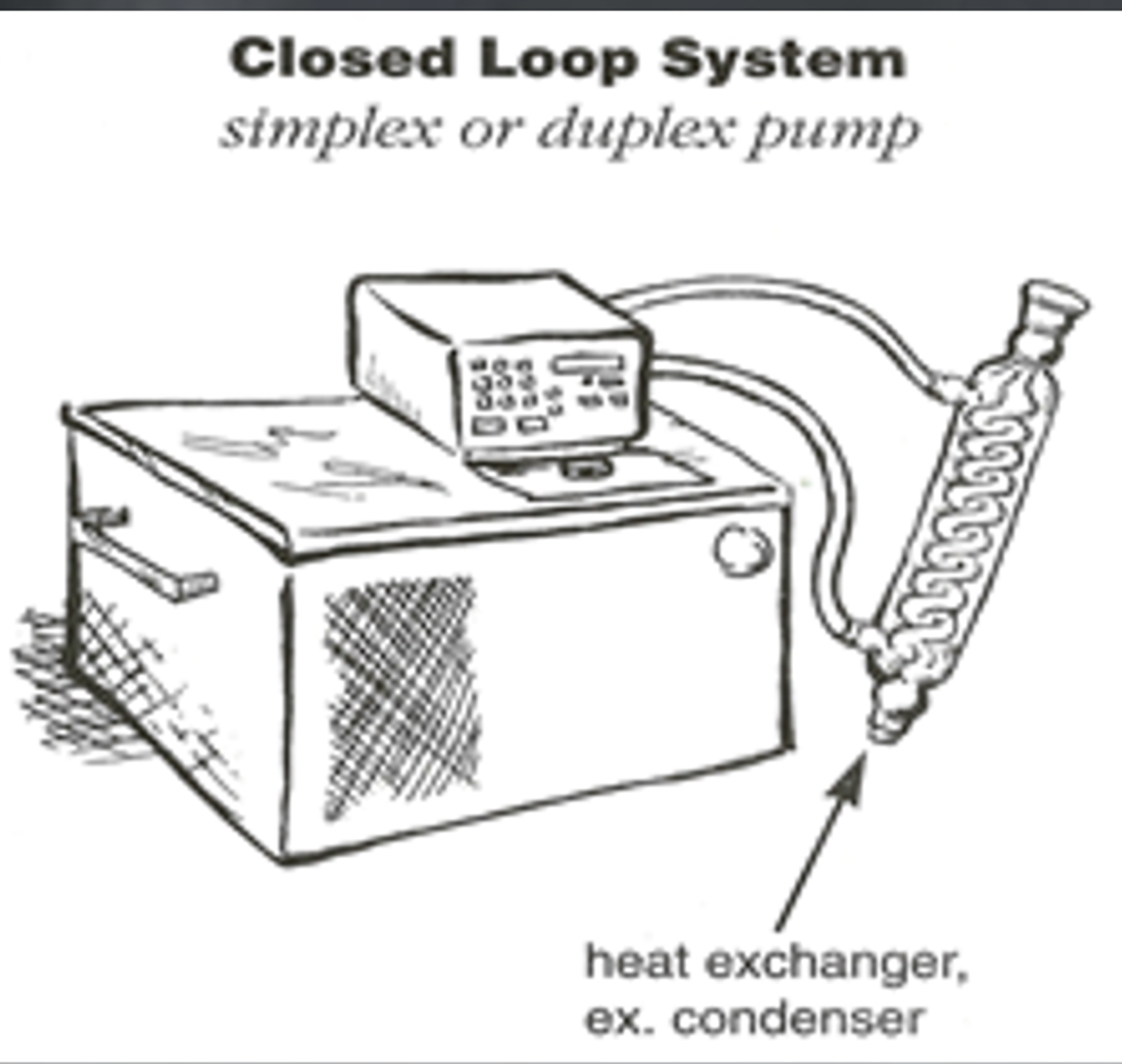

Closed-Loop Circulation

This is generally used in reference to systems or applications where liquid is pumped from a Chiller or Circulating Bath through an external device such as a laser and then returned directly to the Chiller or Circulating Bath. Such systems are “closed” to the atmosphere. Closed-loop circulation may be achieved with both pressure only Simplex and pressure/suction Duplex pumps. All PolyScience Circulating Baths and Chillers are capable of closed-loop circulation.

Cool Command™

A modulated refrigeration system that allows refrigeration to be activated at higher temperatures, providing faster cool downs and optimizing energy efficiency.

Cooling Capacity

This is the amount of heat removal that a refrigerated device, such as a Chiller or Refrigerated Circulator, can provide at a given temperature. It is generally stated in watts or BTUs/hour. It may also be expressed in tons.

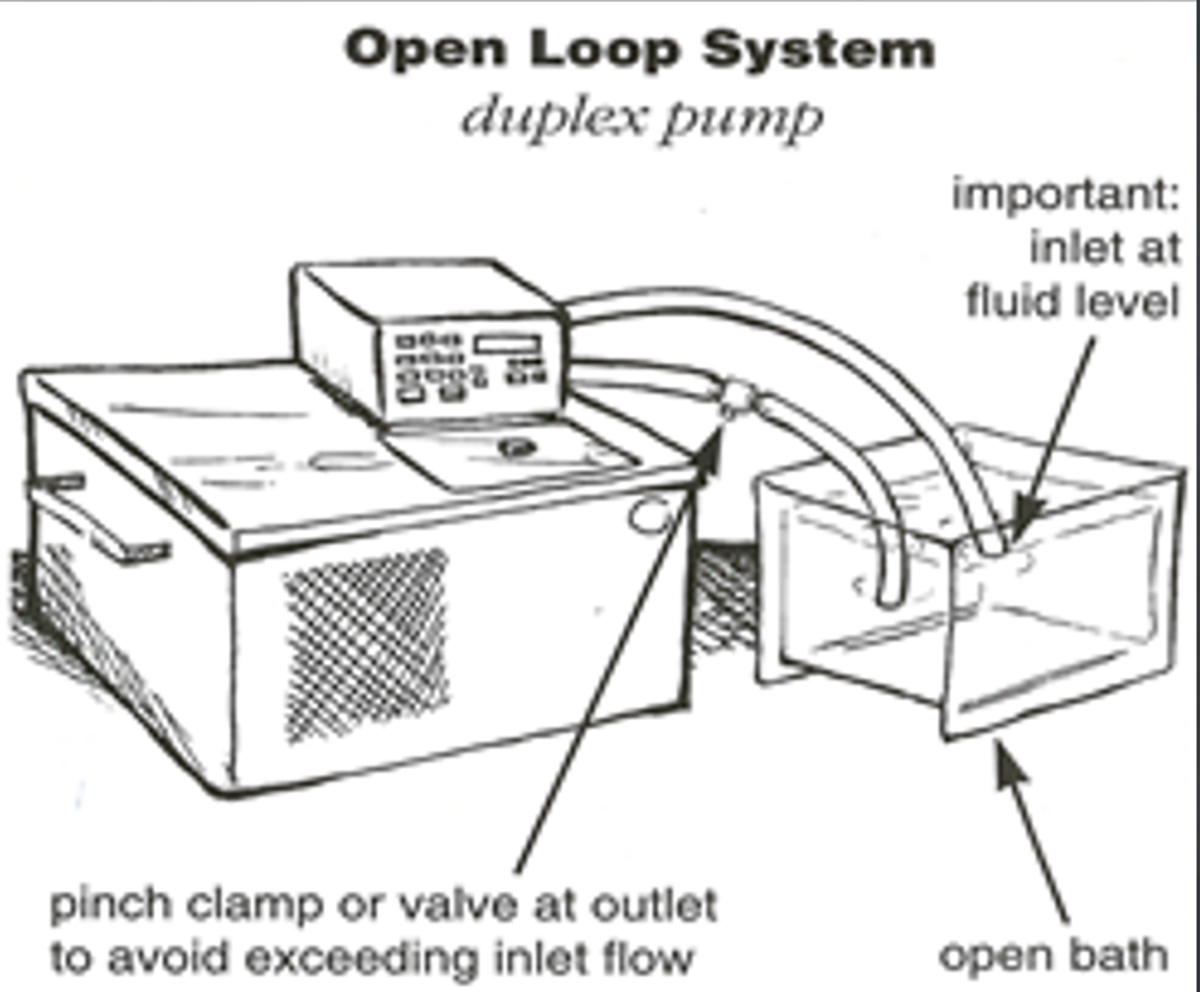

Duplex Pump

A type of pump that provides both pressure and suction, making it suitable for both open-loop and closed-loop applications. PolyScience Circulating Baths with Advanced Series Controllers are equipped with Duplex pumps.

DuraTop™

A precision molded phenolic top plate that remains cooler at high temperatures, is highly resistant to all but the strongest laboratory chemicals, and is easily cleaned and/or disinfected. DuraTop™ is standard on all PolyScience Circulating Baths, Open Tank Systems, Viscosity Baths, Calibration Baths and both the Histology and Coliform Baths.

Flow-Through Cooler

This auxiliary device is often used with open baths or Heated Circulators when rapid cool down or operation at or near ambient temperature is required. A Flow-Through Cooler can also serve as a source of supplemental cooling when used in conjunction with a Refrigerated Circulator or to add cooling to Heated Circulators. Because a Flow-Through Cooler provides refrigeration only, an external pump or other source of circulation is required.

Flow Rate

The volume of fluid pumped in a given amount of time. It is measured using water at a pressure of 0 psi (0.0 bar). Pressure Flow Rate is measured at the outlet port of the unit; Suction Flow Rate is measured at the inlet port.

General Purpose Water Bath

A vessel that can be held at a desired temperature via an integral heater and temperature controller. A General Purpose Water Bath does not incorporate a mechanical means of fluid circulation.

Heat Exchanger

A device used to transfer heat from one material or medium to another.

Heat Load

The amount of heat that is being generated by a device. Heat load calculations are generally used to determine the amount of heat removal needed to maintain the device at a desired temperature.

Heated Circulating Bath

A bath with an integral pump, heater and temperature controller. The circulation of fluid inside the bath reservoir results in better temperature stability and uniformity. All PolyScience Circulating Baths are capable of external circulation.

Immersion Circulator

A combination integral pump, heater and temperature controller that can be secured to a stand-alone tank or reservoir to form a complete Circulating Bath. The PolyScience MX Immersion Circulator can provide precise temperature control for tanks up to 28 liters.

Immersion Cooler

An auxiliary device used to provide rapid cooling for small quantities of liquids or as a replacement for dry ice. An Immersion Cooler can also be used in conjunction with an Open Bath or Heated Circulator to speed cool down or provide more precise control when operating at or near ambient temperature. Cooling is provided via a probe or cooling coil inserted directly in the liquid.

LidDock™

An innovative design that provides for convenient, no-mess reservoir cover placement when adding liquid or working with samples. Available on PolyScience Integrated Circulating Baths, the LidDock™ System allows condensate to drain back into the reservoir, yet doesn’t interfere with controller viewing or operation.

Liquid-to-Air Recirculator/Heat Exchanger

A closed-loop, non-refrigerated system designed to cool an external device by transferring its heat to the air via an integrated heat exchanger.

Liquid-to-Liquid Recirculator/Heat Exchanger

A closed-loop, non-refrigerated system designed to cool an external device by transferring its heat to facility cooling water via an integrated heat exchanger.

Open-Loop Circulation

This is generally used in reference to systems or applications where liquid is pumped from a Circulating Bath to an External Open Tank and then returned to the Circulating Bath. A Duplex pump (pressure/suction), such as that featured on PolyScience Circulating Baths with Advanced Series Temperature Controllers, is required for open-loop circulation.

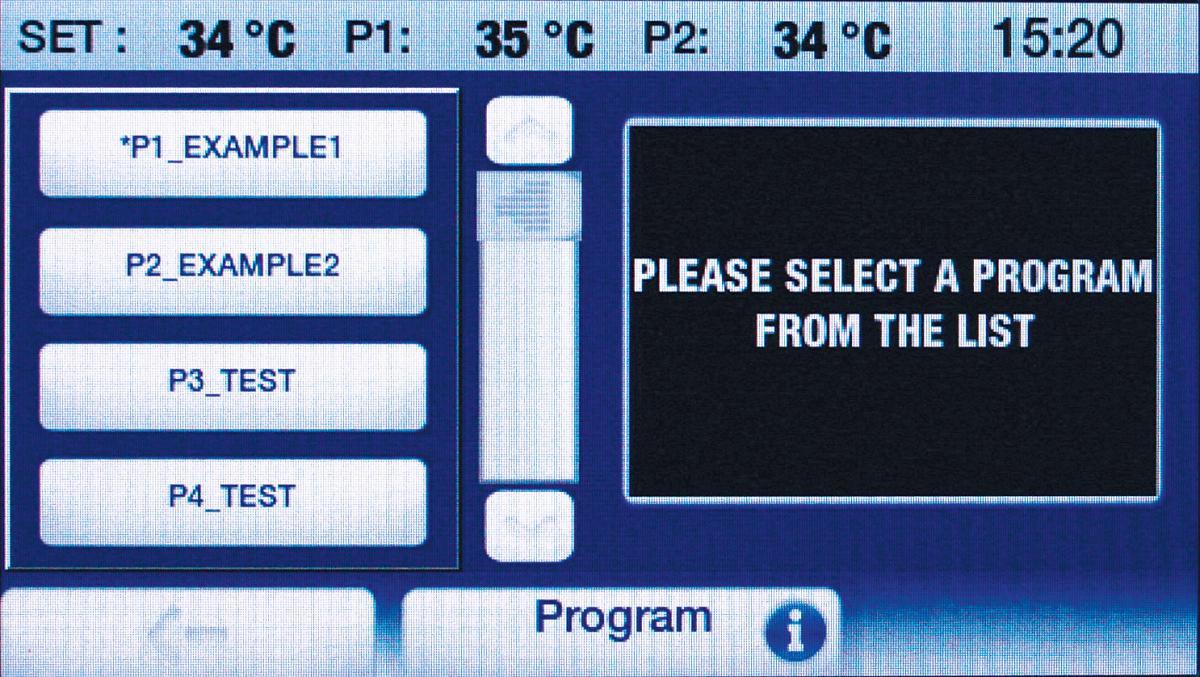

OpenMode Programming

Unique to PolyScience Advanced Programmable Controllers, this feature places no restrictions on the number of time/temperature programs that can be stored or the number of steps a program can have. Limit is dependent on controller memory.

Operating Temperature Range

This is the temperature range that the equipment is capable of achieving and may be broader than the Working Temperature Range. This extended temperature range is particularly useful for the cooling of devices — such as lasers — that must be brought up to a temperature above ambient before operation can begin.

Positive Displacement Pump

Available on select PolyScience Recirculating Chillers, this type of pump generates moderate flow at high pressure. It is best suited for situations where greater head pressure is needed, such as applications where the cooling fluid must be pumped some distance or where in-line pressure is required to activate flow devices.

Pump Pressure

The force of fluid being pumped. The higher the pressure, the greater the distance that the fluid can travel. Lower pressure is better for fragile fluid paths, such as glass tubing. It is measured using water at a flow rate of 0 gpm (0.0 l/min) at the outlet port of the unit.

Recirculating Chiller

Interchangeable with Recirculator and Chiller: See “Chiller/Recirculating Chiller.”

Recirculating Cooler/Heat Exchanger

A closed-loop, non-refrigerated system designed to cool an external device. Cooling is provided by transferring heat from the external device to either the air (Liquid-to-Air Coolers) or to facility cooling water (Liquid-to-Liquid Coolers).

Refrigerant

A compound used in a refrigeration unit to extract heat from a process or internal reservoir. All PolyScience Chillers and Refrigerated Circulators use CFC-free refrigerants.

Refrigerated/Heated Circulating Bath

A bath with an integral pump, heater, refrigeration system, and temperature controller. In addition to low temperature applications, Refrigerated/Heated Circulating Baths offer more precise control for applications that require bath temperatures near or below ambient. All PolyScience Circulating Baths provide internal circulation as well as external circulation capability.

Reservoir Capacity/Bath Volume

This specification provides information on how much liquid the Circulator, Water Bath or Tank will hold when filled to maximum capacity. It does not include the volume of liquid in external tubing or equipment.

Simplex Pump

A type of pump that provides pressure flow only, thus limiting its use to closed-loop applications. PolyScience Circulating Baths with Standard Digital and MX Temperature Controllers are equipped with Simplex pumps.

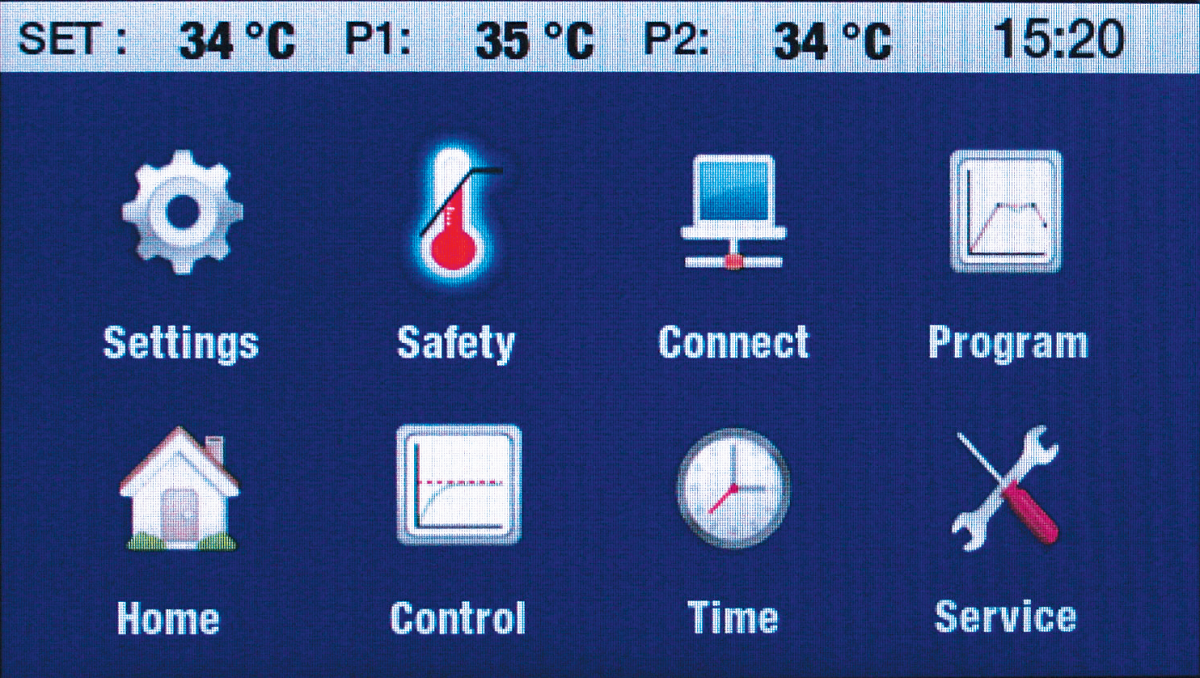

SmartTouch™ Display

An advanced, full-color touch screen display. Featured on PolyScience Advanced Programmable Temperature Controllers.

Specific Heat

This is a measure of a fluid’s heat capacity (the amount of heat per unit mass required to raise its temperature by 1°). The specific heat of water is 1 BTU/lb °F (4.19 KJ/ kg K). PolyScience Circulators with Advanced Series Temperature Controllers can be tuned for use with specific fluids to enhance performance and temperature control.

Suction Pressure

This is the pressure generated by the pump at the fluid intake of a Circulator equipped with a Duplex (pressure/ suction) pump. It is measured using water at a flow rate of 0 gpm (0.0 l/min).

Swivel 180™ Rotating Controller

A (patent-pending) PolyScience exclusive that allows independent positioning of the Circulating Bath Temperature Controller, thus allowing the operator to keep the temperature display in sight anywhere within a 180° viewing radius. Swivel 180™ is standard on Advanced and Standard Temperature Controllers.

Temperature Accuracy

This represents how well the instrument’s measured temperature value corresponds to that of a calibrated standard. For example, the displayed bath temperature in a Circulating Bath with a set-point of 25.00°C and a temperature accuracy of ±0.25°C may actually be as low as 24.75°C or as high as 25.25°C. PolyScience Circulators, Digital Water Baths and Chillers feature a calibration offset that allows the operator to match the displayed temperature to that of an external device or calibrated temperature standard.

Temperature Stability

This represents how precisely an instrument maintains a set-point temperature and is expressed as a plus/ minus value. For example, the actual bath temperature in a circulating bath with a set-point of 23.20°C and a temperature stability of ±0.01°C may vary from 23.19°C to 23.21°C.

Temperature Uniformity

This represents how closely liquid temperatures at various locations within the reservoir of the water bath match. In general, Circulating Baths provide better temperature uniformity than General Purpose Water Baths.

Thermal Conductivity

This is a liquid, gas, or solid’s ability to conduct heat. Water (with a thermal conductivity value of 0.6) is a good conductor of heat, while air (TC value of 0.025) is a much poorer heat conductor.

Time/Temperature Programming

Standard on Advanced Programmable Temperature Controller, this feature allows the operator to create and store frequently used test protocols and/or complex ramp and soak profiles for later retrieval and use. The PolyScience Advanced Programmable Controller features OpenMode Programming which has no set limits on the number of programs that can be stored or the number of steps in a program.

Thermal Loss/Thermal Gain

Also referred to as Heat Loss or Heat Gain, this is the change in temperature that may occur due to ambient temperature or other environmental conditions. Thermal loss/gain can be minimized through the use of a reservoir cover and by insulating external tubing. Select PolyScience Circulators and Chillers also feature external temperature control capability which can be used to compensate for heat loss/gain when circulating to external applications.

Turbine Pump

Available on many PolyScience Recirculating Chillers, this type of pump provides moderate flow at higher pressures. It is well suited to applications that require higher pressure or experience a higher pressure drop, such as when using high viscosity fluids, smaller tubing diameters or pumping higher or further from the cooling product and the application.

Variable-Speed Pump

Advanced Series Temperature Controllers are equipped with Variable-Speed Pumps which allow adjustment of pump speed and flow rate throughout most of the range of the pump motor. This adjustability allows the user to compensate for fluid viscosity and achieve optimal uniformity within the bath. It also provides adjustment of flow rate when pumping to an external application.

Viscosity

A measure of the resistance of a fluid to flow. The more viscous (thick) a fluid is, the more difficult it is to pump.

Water Bath

A water bath refers to a heating, bath-style device used to thermoregulate temperature as a water bath, which could include Circulators. PolyScience uses this term to describe a “General Purpose Water Bath.”

Water-Cooled (Chiller)

A type of chiller that transfers heat absorbed from the process fluid to another liquid, such as facility water from a cooling tower, as opposed to transferring the heat to the ambient air. See also “Air-Cooled (Chiller).”

WhisperCool™ Environmental Control System

Our patented adaptive technology noticeably reduces operational noise, optimizes compressor and evaporator performance, decreases overall energy consumption, and prolongs compressor life. It is standard on select PolyScience Recirculating Chillers as well as -40°C 7 liter and all 15 liter and larger Refrigerated/Heated Circulating Baths.

Working Access/Bath Opening

This dimension provides information on the amount of available space within the Circulator or Water Bath for glassware, sample holders, test tube racks, etc.

Working Temperature Range

This is the temperature range over which the equipment can achieve and control without auxiliary heating or cooling at the stated temperature stability specification.