Chillers provide heat removal for a wide variety of processes and equipment. When properly sized and selected, a chiller increases production speed and accuracy, protects valuable process equipment, and reduces water consumption and related costs. If it is undersized, the chiller will not cool properly; if it is oversized, it will be inefficient due to excessive cycling. In addition to having an adequate cooling capacity, the chiller must deliver the cooling fluid at the proper pressure and flow rate.

Here are the four basic factors that affect chiller sizing and selection:

This is the coolant temperature at the inlet of your process or equipment. It is important to measure the temperature at this point to allow for coolant heating as it travels from the chiller to the process. The longer the distance to be covered, the higher the potential heat gain. This heat gain can be minimized by insulating the cooling line and positioning the chiller as close as practical to the equipment or process being cooled.

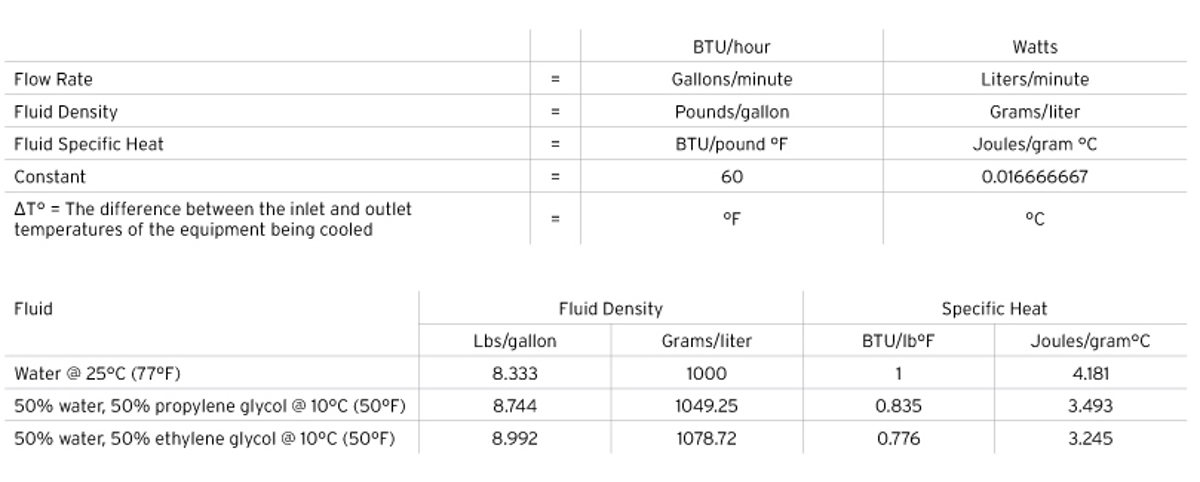

This is the amount of heat that needs to be removed. It is usually expressed in BTUs/hour or watts. The heat load value is often provided by the equipment manufacturer. If not, it can be calculated using the following formula:

Heat load = Flow rate x Fluid density x Fluid specific heat x Constant x ΔT°

These parameters are normally provided by the equipment manufacturer and are a function of the surface area and the heat transfer characteristics of the process/material being cooled. It is crucial that your chiller deliver coolant at the proper flow rate and pressure. If the flow rate or pressure is too high, the equipment being cooled may be damaged; if it is too low, the heat removal will be inadequate. PolyScience can help you specify the type and size of coolant pump most suitable for your needs.

The final factor influencing chiller/heat exchanger selection is how the heat removed will be dissipated. Chillers with air-cooled condensers exhaust heat into the surrounding air and require only power and ventilation for operation. Chillers with water-cooled condensers transfer heat to the facility's cooling water supply.

Naturally, there are other factors – such as heating capability, external temperature tracking, deionized water capability, etc. – that affect how a chiller is ultimately configured. PolyScience will take all of these into consideration when helping you select the best chiller for your particular application. Here is a summary of the information you'll need to know to ensure that the chiller you select is the best one for your application:

- Desired coolant temperature at the inlet to your equipment or process

- Anticipated heat load, as calculated or specified by the equipment manufacturer

- Cooling fluid flow rate and pressure requirements

- Maximum room (ambient) temperature where the chiller will be located

- Internal heat dissipation, space, and portability needs

- Special requirements, such as remote temperature tracking or piping for deionized water

It is generally recommended that 20% to 50% be added to the calculated heat load to provide a safety factor if the chiller will be operated at ambient temperatures above 20°C (68°F), at high altitude, or if the heat output of the device is variable. This will also provide a margin of safety for future cooling needs. That said, resist the temptation to build more of a safety margin into your chiller than is necessary; an oversized chiller will not cool your equipment any more effectively, but will cost more to purchase and operate.

The most common and acceptable coolant is a mixture of 50% distilled water and 50% glycol (polycool EG-25). This combination will provide the best results for set-point temperatures between -25°C and +80°C (-13°F and +176°F). Although ethylene glycol is not required for set-point temperatures above freezing (0°F/+32°F), it is highly recommended as glycol helps lubricate pump seals and fluid temperatures inside the chiller may be below freezing.